This procedure is for the installation of an underdrive pulley. This requires removal of all 3 drive belts and possibly the starter. Nissan recommends changing drive belts every 30,000 miles. They should be checked periodically too. This procedure applies to the VE30DE engine, but is very similar for the VG30E.

My car was leaking oil out of the front main seal (behind the crankshaft pulley) so I figured if I was going to have to take off that pulley, I should go ahead and put a better one back on. For the VE engine (1992-1994 SE only), ASP Racing sells a lightened, smaller crankshaft pulley:

Auto Specialties underdrive pulley systems increase engine horsepower by reducing the amount of power required to drive external accessories. For example, the alternator, power steering, water pump and air conditioner all rob horsepower from the engine. By replacing factory-sized crank and accessory drive pulleys with a resized pulley, the accessories are slowed, resulting in more horsepower available to drive the rear wheels. Typically, a set of Auto Specialties street pulleys will increase output by 12 to 15 horsepower, resulting in quarter mile time improvements of .2 to .25 seconds.

I got mine at RPMoutlet.com. For the VG engine (89-91 SE and 89-94 GXE), Unorthodox Racing sells a lightened, smaller pulley. You can get this from Courtesy Nissan.

Becuase the new pulley is smaller, you will need smaller sized drive belts which run about $10 each from most parts stores. Here are the Gates parts numbers for the belts you need (note: ASP gives a different part number for the power steering belt, but this is the correct one). I got mine at PepBoys and they are Dayco brand; the numbers are easily converted to Dayco numbers - 325K5, 378K4, 460K4. The number next to K means the number of grooves in the belt and the other number has something to do with the length (probably the circumference).

| | VE30DE | VG30E |

| Alternator | K050323 | K040292 |

| Air Conditioning | K040460 | K040460 |

| Power Steering (also drives water pump) | K040378 | K040395 |

As you can see, the new belts fit just inside the old belts:

Tools you will need:

Tools you will need:

various sockets: 10,12,14 and 27mm (for the crankshaft pulley bolt); you may need one or two other sizes, but nothing special besides the 27

12mm open end wrench

socket extension

torque wrench

breaker bar

flat head screwdriver

impact wrench would be very helpful, but not necessary

maybe: pulley remover

This procedure isn't that complicated, but if you haven't ever changed drive belts, it may be a good idea to have someone else check over your work before you put everything back together (especially important for power steering and alternator belts). Read through the instructions first before beginning any work. Also, you should buy a new front oil seal for your car. It's about $3 from Courtesy Nissan and maybe $5 or 6 from a local dealer; you'll have everything off to change it and you wouldn't want to have to do this again if it starts leaking in a few weeks from now. The part for the VE engine is 13510-97E10; I'm not sure of the part number for the VG.

First, remove the right front wheel and remove the splash shields that cover the side and below the drive belts. There are a couple 10mm bolts holding these on. You should now be able to see the crankshaft pulley and drive belts

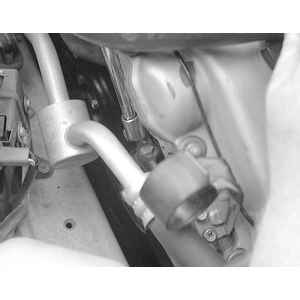

Start by loosening the 12mm bolt on the air conditioner's idler pulley - this is the small pulley just in front of the A/C compressor. This will be more of a pain if you have ABS, but it's still not that bad. I used the flat open end of a 12mm wrench to get the bolt and then loosed it that way. Dont remove this bolt, just loosen it a few turns. Now there is a bolt pointing straight up just behind that pulley that you need to adjust to move the pulley down (see picture below). If this bolt is hard to turn, make sure the bolt through the middle of the idler pulley is loose enough; dont force it or you could damage the idler pulley tracks. You need to lower it enough so the belt has enough slack to pull off of the A/C compressor. The pictures below are with the large radiator hose removed so you can see where the bolt is.

Start by loosening the 12mm bolt on the air conditioner's idler pulley - this is the small pulley just in front of the A/C compressor. This will be more of a pain if you have ABS, but it's still not that bad. I used the flat open end of a 12mm wrench to get the bolt and then loosed it that way. Dont remove this bolt, just loosen it a few turns. Now there is a bolt pointing straight up just behind that pulley that you need to adjust to move the pulley down (see picture below). If this bolt is hard to turn, make sure the bolt through the middle of the idler pulley is loose enough; dont force it or you could damage the idler pulley tracks. You need to lower it enough so the belt has enough slack to pull off of the A/C compressor. The pictures below are with the large radiator hose removed so you can see where the bolt is.

Now you need to remove the alternator belt. Loosen (do not remove) the bolt at the bottom of the alternator that goes into the alternator adjustment bolt (first picture). Also, loosen the alternator pivot bolt near the top of the alternator (second pic). Now you can loosen the alternator adjusting bolt (third pic). In my case, the bolt loosened but alternator did not move, just move the alternator with your hand to the point where the bolt is tight again. Loosen this until you can pull this belt off.

Now you need to remove the alternator belt. Loosen (do not remove) the bolt at the bottom of the alternator that goes into the alternator adjustment bolt (first picture). Also, loosen the alternator pivot bolt near the top of the alternator (second pic). Now you can loosen the alternator adjusting bolt (third pic). In my case, the bolt loosened but alternator did not move, just move the alternator with your hand to the point where the bolt is tight again. Loosen this until you can pull this belt off.

Now you need to remove the power steering belt (which also runs the water pump). There is another idler pulley for this system. Just loosen the center nut for that and lower the idler pulley until you have enough slack to remove the belt.

Now you need to remove the power steering belt (which also runs the water pump). There is another idler pulley for this system. Just loosen the center nut for that and lower the idler pulley until you have enough slack to remove the belt.

If you are not putting on an underdrive pulley and just want to change drive belts, skip the next couple steps

If you are not putting on an underdrive pulley and just want to change drive belts, skip the next couple steps

Remove bolt in the center of the crankshaft pulley. This is where you need the 27mm socket. This bolt is on very tight; if you have an impact wrench, this is a great time to use it. Otherwise, you'll probably need a long breaker bar. Chiltons recommends removing the starter and placing a flat blade (your hubcap removal tool in your Nissan jack set in the trunk should work fine) in the teeth of the flywheel/driveplate.

If you have a manual transmission, put the car in 5th gear. The starter is easily removed; if you are going to remove it, you should unplug the negative terminal of the battery first so you dont short anything while removing the starter's power wire. The starter is only held on by a large wire, one 14mm nut and one 14mm bolt. If you remove the rubber protective covering over the large wire, you will find a nut under there; just remove that and the large wire will come off. You will also need to unclip a smaller ground wire from it's harness. Then you can remove the 14mm nut and bolt that hold the starter onto the transmission. After these are loose, the starter will just pull off and you should be able to see the flywheel.

If you have an automatic, there should be a small cover over the lower part of the transmission that you can remove to see the driveplate

If you have an automatic, there should be a small cover over the lower part of the transmission that you can remove to see the driveplate

Then wedge something in between the teeth and prop it against something solid. You should now be able to break loose the crankshaft pulley bolt.

Now you can remove the crankshaft pulley. Mine could be pulled off by hand; if not, a 2 or 3 jaw puller can be used to pull it off. You will notice how much larger and heavier the stock pulley is compared to the new pulley.

Now you can remove the crankshaft pulley. Mine could be pulled off by hand; if not, a 2 or 3 jaw puller can be used to pull it off. You will notice how much larger and heavier the stock pulley is compared to the new pulley.

The old oil seal needs to be removed now. It is just around the inner edge of where the pulley was. Use a flat head screwdriver to gently pry this out. Be very careful not to scratch or damage anything other than the seal. Now the new seal just needs to be pushed in place (you should lube the outer edge with some engine oil, the inner edge is already lubed). Put it in place and gently push the edges in; I used a rubber mallet to help push it in. The first picture shows the seal still on and the second shows the seal removed.

The old oil seal needs to be removed now. It is just around the inner edge of where the pulley was. Use a flat head screwdriver to gently pry this out. Be very careful not to scratch or damage anything other than the seal. Now the new seal just needs to be pushed in place (you should lube the outer edge with some engine oil, the inner edge is already lubed). Put it in place and gently push the edges in; I used a rubber mallet to help push it in. The first picture shows the seal still on and the second shows the seal removed.

The new pulley will be very tight to get on. Some have hammered it on, but I would NOT recommend this. I used my dremel to shave off some material from the inside diameter until it fit better. On mine, I could feel a small difference in diameter between the inside edge of the new pulley and the rest of the inside diameter; I ended up dremeling the inside until it was all the same diameter as the end portion. Just use sandpaper, a dremel or whatever to remove a small amount of metal in there, but try to do it in a circular way so it's even throughout. When I was done with this, the new pulley fit on better. I got it on part way and then put the large bolt in the middle and tightened it to help push the pulley on. Now you need to torque the pulley bolt to 123-130 ftlbs for the VE or 90-98 ftlbs for the VG. You can now put the starter back on (or cover plate for the automatic tranny). Also, you can now reconnect the battery if you unplugged it.

The new pulley will be very tight to get on. Some have hammered it on, but I would NOT recommend this. I used my dremel to shave off some material from the inside diameter until it fit better. On mine, I could feel a small difference in diameter between the inside edge of the new pulley and the rest of the inside diameter; I ended up dremeling the inside until it was all the same diameter as the end portion. Just use sandpaper, a dremel or whatever to remove a small amount of metal in there, but try to do it in a circular way so it's even throughout. When I was done with this, the new pulley fit on better. I got it on part way and then put the large bolt in the middle and tightened it to help push the pulley on. Now you need to torque the pulley bolt to 123-130 ftlbs for the VE or 90-98 ftlbs for the VG. You can now put the starter back on (or cover plate for the automatic tranny). Also, you can now reconnect the battery if you unplugged it.

Now you are ready to put the belts back on. This is just the opposite of how you removed them - put new belt over the pulleys and tighten the adjustment bolt and then tighten a bolt to lock the adjustment (and for alternator, tighten pivot bolt). If your belts are too loose, they may make a squeling sound when you start the car and may slip a little. If they are too tight, they could cause lots of other problems so it's important to get the tension right. The picture below shows the test point for each bolt as indicated by the arrow. If you push or pull down on this point it should move a certain distance for each new belt. Alternator: 6.5-7.5mm, A/C: 5-6mm, power steering: 6.5-7.5mm. This is where it would be helpful to have someone who has done drive belts before to check the tension for you to be sure.

Once the belts are on and tighten, check the 2 idler pulleys and the alternator adjustment bolts to make sure they are all tight. Start up the car and take a look at the belts and pulley. My pulley looked like it was a little off center, but I realized it was just the washer in the middle of the pulley was tricking me because of the silver color of the pulley and the black of the washer. Look at the edges to be sure. Check that all the belts are turning smoothly and are not at all crooked or not in their grooves. Now just replace the splash shields and that should be it. Check the pulley and belts again in a couple days just to make sure everything is still in place :)

Once the belts are on and tighten, check the 2 idler pulleys and the alternator adjustment bolts to make sure they are all tight. Start up the car and take a look at the belts and pulley. My pulley looked like it was a little off center, but I realized it was just the washer in the middle of the pulley was tricking me because of the silver color of the pulley and the black of the washer. Look at the edges to be sure. Check that all the belts are turning smoothly and are not at all crooked or not in their grooves. Now just replace the splash shields and that should be it. Check the pulley and belts again in a couple days just to make sure everything is still in place :)

User is solely responsible for any damage resulting from this procedure

|