|

Below are the procedures that I used in performing the replacement of six of

my fuel injectors. I put them on this web page to serve as guidance for you,

but do not guaranty the results nor do I proclaim this is

the correct procedure, though I reference the Nissan Factory Service

Manual, hereinafter ("FSM"), throughout. If you have any doubt on your

capability in performing this replacement, take your car to a certified

mechanic.

What you need:

1. Upper intake

manifold gasket; part number 14033-89E00

2. Lower intake manifold gasket;

part number 14032-89E01

3. Throttle body gasket; part number

16175-89E10

4. A.A.C valve gasket

5. New / remanufactured fuel

injectors

a. see the picture below, which depicts the

two injectors with different connectors.

b. The 90 -91

injectors have the metal clip (smaller) harness connector and the 92-94's have

clip-type (bigger) harness connector.

c. Also, Nissan made

both blue and black dot injectors for our cars. I have been told you can use

either one, but can't mix and match. I doubt it would hurt mixing and matching

though, just so long as you get the right one for your car. The dot is on the

harness connector.

d. I picked up my remanufactured units

for $37.95/ injector after the core deposit refund from Direct Automotive

Products (www.directauto.com)

The injector on the left is a 92-94 injector, and the right is a 90-91,

and probably an 89 too.

The steps I performed:

1.

Release fuel pressure to zero

a. I did this by

unhooking the upper hose from the fuel filter after pulling the fuel pump

fuse

2. Separate the accelerator cables from the throttle

body.

a. they easily just slide off. Tilt the

butterfly valves back to get them.

b. Remove the cabling

and routing from the intake plenum.

3. Remove spark plug wires from spark

plugs.

4. Remove the intake elbow leading to the throttle

body.

a. there are three bolts, the middle one is the

longer one and routes the spark plug wires.

b. These bolts

are torqued at 13 - 16 ft lbs.

· For steps 6 - 9, basically remove necessary

hoses and vacuum lines so you can free the plenum for removal. I took notes on a

few of the items I might have forgotten when putting things back

together.

5. Remove the A.A.C. valve

a. there

are four 5 mm hex bolts holding this in. remove the harness connector

also.

b. There is an "S" shaped hose connecting the AAC

valve to the plenum, remove this also.

6. Disconnect throttle

sensor

7. Disconnect the P.C.V. hoses behind the intake

plenum

8. Disconnect vacuum hoses under the throttle body, from the

E.G.R. control valve, master brake cylinder ,etc.

9. Remove the E.G.R.

flare tube

a. this is held on by two nuts. I think

they are 10mm in size.

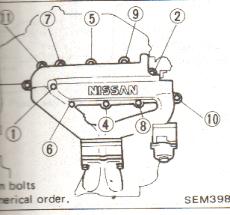

10. Remove the upper intake

plenum

a. there are eleven six

millimeter hex bolts that hold down the plenum at 13 - 16 ft

lbs.

b. There is a special torque

sequence that I observed in both loosening them and tightening them down. Please

refer to the picture at the bottom of the screen for that sequence.

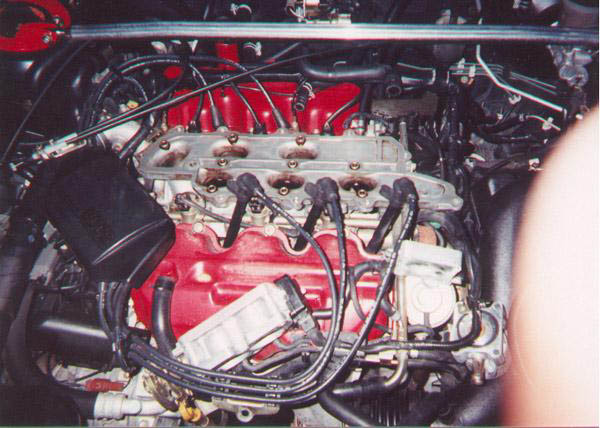

Less the spark plug wires and

the throttle body (my procedure keeps it attached to the plenum), your engine

should look something like the above before taking the lower intake manifold

off. Pictures are courtesy of Matt Blehm.

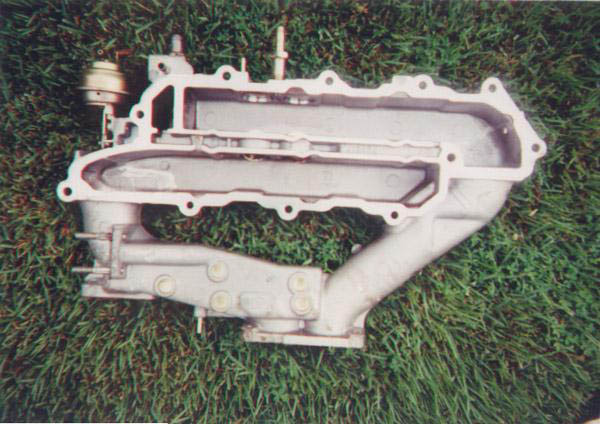

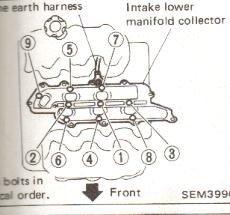

11. Remove the lower

intake manifold collector from the

engine.

a. Use the loosening

sequence below for taking the manifold off and putting it back on. Again,

reference the picture at the bottom of the screen.

12. Remove the engine

earth harness from behind the plenum.

13. Remove the fuel injector

harness wires

a. For the

92,93,94's this is easy, as you just apply pressure on the harness and

pull

b. For the 90 and 91's (and

presumably 89's) there is a metal wire clip that you must pull out or partially

out to remove the connector.

14. Remove fuel

injector(s)

a. I used a pair

of pliers and gripped them tightly, turning the injectors back and forth before

pulling upward. All came out somewhat easily, except my last

one.

b. There should be two O

rings per injector for the 90 -91 injectors. I am not sure the 92,93,94

injectors have two. The lower O ring will likely stay in the fuel rail hole upon

removal of the injector. Just stick your finger in and retrieve it. Be sure to

replace with new "O" rings, per the FSM.

15. Replace

injector(s)

a. I applied motor

oil to the O rings and carefully inserted the new fuel injector. Instead of just

pushing downward immediately, you should turn it back and forth, while applying

downward pressure. You will see and feel the injector seat in how it should

be. Before replacing, assure that the new ones spec out

correctly with regard to resistance. The range of resistance allowed by Nissan

is 10 –14 ohms.

16. Clean intake plenum, lower intake

manifold, and intake runners.

a. I used Carb clean and a Valvoline product. I sprayed a good amount of Carb

clean down the intake runners and used a cloth to wipe the dirt out. You may

want to try a toothbrush.

b. Be

sure to completely scrape away all remaining gasket material on both surfaces so

as not to allow an intake leak after assembly.

17. Reinstall all parts in

reverse order, keeping in mind the torque sequence and use the torque wrench so

as to tighten the following to these torque specifications, per the

FSM:

a. plenum hex bolts 13

- 16 ft. lbs.

b. lower intake

manifold hex bolts, 13 - 16 ft.

lbs.

c. A.A.C valve bolts -

4.6 - 6.1 ft lbs.

d. intake

elbow bolts 13 - 16 ft. lbs.

|